Overview

Air stripping removes chemicals called “volatile organic compounds” or VOCs from wastewater, especially ammonium (NH4+). VOCs have low boiling points and evaporate easily at room temperature.

Air stripping

How does it work

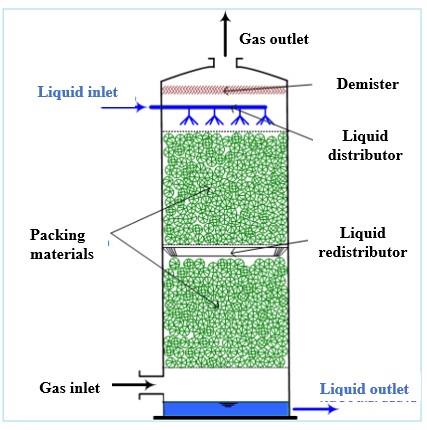

Air Stripping usually consists of large tank filled with a packing material, liquid distributor and redistributor, demister which is responsible for retaining the water, only allowing the gas to escape. With the help of this technique, wastewater and air can interact closely. This results in the transfer of volatile compounds from wastewater into the gas. The off-gases containing VOCs are then treated in an air pollution treatment system. Air stripper (5–12 meters high) only requires a minimal surface area and is permanently installed.

Air stripping design

Types of air Strippers

The two most widely used air stripper types are packed-column and low-profile sieve tray, and they both operate on the same principles. The primary distinction is that the packed-column air stripper uses packing materials rich in bio media, which boots air-water contact and maximizes the effectiveness of VOCs removal. As a result, packed-column air stripper is able to eliminate 80–90% of VOCs, making them more effective in cleaning up pollutants than low-profile sieve tray air stripper.

-

Packed-column: The water containing the VOCs enters the top of the column and flows down through packing material. At the same time, air flows up through the. As the water and air pass each other, the VOCs are transferred from the water phase to the air phase. The water phase leaves the bottom of the column with most of the VOCs removed. The VOCs that are now in the air phase exit from the top of the column.

Examples of packing material for air stripping towers

-

Low-profile sieve tray: Low-profile air stripper operates in a similar way to packed-column air stripper. The difference is that the water flows across trays that are perforated with small holes, over a weir to the next lower tray, tray by tray until the water exits the bottom of the stripper. Air is bubbled through holes in the trays. The VOCs are transferred from the water phase to the air phase as the air is bubbled through the water on the trays.

These aforementioned air strippers are designed to maximize air-water contact while minimizing space.

Design parameters

|

No. |

Parameter |

Value |

|

1 |

Hydraulic loading rate |

2,45 – 4,90 m2/m3*hour |

|

2 |

Height of the packing materials |

6,1 – 7,6 m |

|

3 |

pH |

10,8 – 11,5 |

Effect of the packing height, hydraulic loading rate and air-water ratio on ammonium removal efficiency

|

Efficiency of stripping column |

6,6 m packing height |

7,9 m packing height |

||

|

Hydraulic loading rate (m3/m2*hour) |

Air-water ratio (m3/m3) |

Hydraulic loading rate (m3/m2*hour) |

Air-water ratio (m3/m3) |

|

|

80 |

9 |

1700 |

9,7 |

1500 |

|

85 |

7,9 |

1800 |

8,6 |

1600 |

|

90 |

1,7 |

2100 |

7,2 |

1900 |

|

95 |

|

|

5 |

3000 |

|

98 |

|

|

4,8 |

6000 |

Air Stripping (Source: https://www.monroeenvironmental.com)

Air stripping is a desorption process used to remove VOCs from wastewater

-

In both inorganic and organic chemistry, stripping is used for the removal of volatile organic substances, sulphur compounds (H2S, phosphine) and NH3. Stripping is normally carried out on the concentrated partial flow;

-

Air stripping is used in the pharmaceutical sector for the removal of chlorinated solvents from wastewater;

-

In viscose production, air stripping is the standard technique for the removal of CS2 from wastewater;

-

Air stripping is currently being used for cleaning groundwater in soil remediation, possibly followed by an airbased active carbon filter or bio-filter. The following compounds are primarily removed when stripping groundwater: Aromatic compounds (BTEX) and/or volatile chlorinated hydrocarbons (VOCs, incl. trichloro ethene, perchlore ethene, tetrachloro methane, chloroform).

The flow of water through an air stripping may take only a few minutes or longer, depending on the size of the device, the rate water flows and contaminant concentrations.

The Pros and cons of Air Stripping

|

Advantages |

Disadvantages |

|

|

Operation and maintenance

Regular O&M includes the following activities:

-

Testing and calibrating equipment

-

Maintaining pumps and blowers

-

Inspecting the tower periodically for fouling

-

Clarifying the influent before stripping

The company provides environmental profile and construction services, operation, maintenance - maintenance of reputable wastewater treatment systems

Nanoen operates in the environmental sector and has gained the trust of customers for its honesty, dedication, and responsibility to customers and company products.

With a team of experienced staff, we offer comprehensive services from environmental profile consulting to design and construction, operation of environmental treatment systems, microbial supply, and sludge pressing.

Nanoen is always ready to provide the best service experience, tailored to the needs of our customers.

Nanoen

Address: 661E/29, Vo Van Kiet Street, Binh Yen A Quarter, Long Hoa Ward, Binh Thuy District, Can Tho City

Hotline: 0941.777.519 - 0907.803.678 - 0901.229.798

Email: nanoentech@gmail.com

Facebook: www.facebook.com/nanoentech